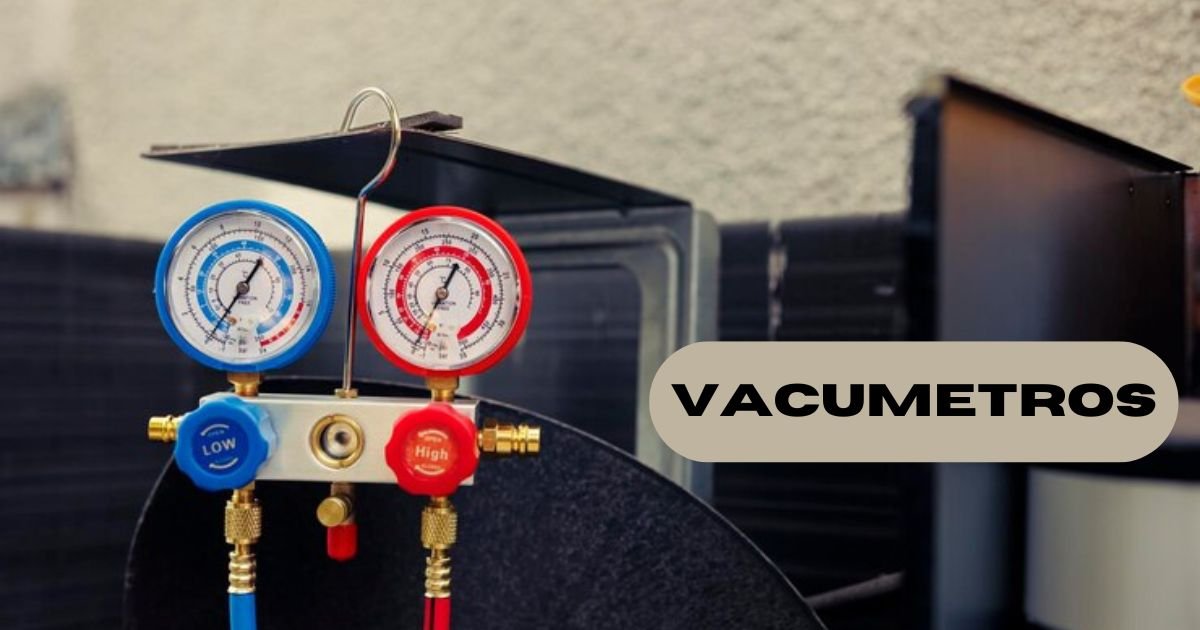

Vacumetros, commonly known as vacuum meters, are crucial instruments used to measure the pressure in a vacuum system. These devices help monitor the efficiency and functionality of vacuum systems across various applications. Whether you’re working in a laboratory, manufacturing facility, or in research and development, understanding how to use and interpret vacuum meters can significantly impact your operations.

What is a Vacumetros ?

A vacuum meter is a device designed to measure the pressure in a vacuum system. Unlike standard pressure gauges, vacuum meters measure pressures below atmospheric levels. They are essential for ensuring that vacuum systems operate within their required pressure ranges, which is critical for processes that rely on precise vacuum conditions.

Types of Vacumetros

Mechanical Vacuum Gauges

Mechanical vacuum gauges use physical principles to measure vacuum pressure. Common types include Bourdon tube gauges and diaphragm gauges. These devices are simple to use and provide reliable readings for many industrial applications.

Thermal Conductivity Gauges

Thermal conductivity gauges measure vacuum pressure by assessing the thermal conductivity of the gas within the vacuum system. They are highly sensitive and suitable for applications requiring precise measurements.

Ionization Gauges

Ionization gauges work by ionizing gas molecules within the vacuum and measuring the resulting electrical current. They are used for measuring very low pressures and are essential in high-vacuum and ultra-high-vacuum applications.

Capacitance Manometers

Capacitance manometers measure vacuum pressure based on the changes in capacitance caused by variations in pressure. They are known for their accuracy and are used in environments where precise pressure measurement is crucial.

Understanding Vacuum Measurements

Vacuum Pressure Units

Vacuum pressure is often measured in units such as Torr, Pascal (Pa), or millibar (mbar). Understanding these units is vital for interpreting gauge readings accurately. Each unit represents a different scale of measurement but can be converted between them as needed.

Absolute vs. Gauge Pressure

Absolute pressure refers to the total pressure within a system, including atmospheric pressure, while gauge pressure measures pressure relative to atmospheric pressure. Vacuum meters typically measure absolute pressure, which is crucial for determining the true vacuum level.

Applications of Vacumetros

Laboratory Research

In laboratories, vacuum meters are used to create and maintain precise vacuum conditions for experiments and processes. Accurate measurements are essential for achieving reliable and reproducible results.

Manufacturing Processes

Vacuum meters play a critical role in various manufacturing processes, including coating, packaging, and material processing. Ensuring that vacuum levels are within specified ranges helps maintain product quality and process efficiency.

Aerospace and Automotive Industries

In aerospace and automotive industries, vacuum meters are used to test and verify the integrity of components and systems. Accurate vacuum measurements are essential for ensuring the performance and safety of critical equipment.

How to Choose the Right Vacumetros

Application Requirements

When selecting a Vacumetros , consider the specific requirements of your application. Different types of vacuum meters are suited for different pressure ranges and environments, so choose a meter that matches your needs.

Measurement Range

Ensure that the vacuum meter you choose covers the pressure range required for your application. Using a meter with an appropriate range ensures accurate and reliable readings.

Calibration and Maintenance

Regular calibration and maintenance are essential for ensuring the accuracy and longevity of your vacuum meter. Follow the manufacturer’s guidelines for calibration and maintenance to keep your device in optimal condition.

Common Issues with Vacumetros

Inaccurate Readings

Inaccurate readings can result from various factors, including incorrect calibration, contamination, or damage to the vacuum meter. Regular maintenance and proper handling can help prevent these issues.

Sensor Failure

Sensor failure can occur due to exposure to harsh conditions or improper use. Ensure that your vacuum meter is used within its specified limits and protected from environmental factors that could cause damage.

Calibration Drift

Over time, vacuum meters may experience calibration drift, leading to inaccurate measurements. Regular calibration checks are necessary to ensure that the meter provides accurate readings.

Conclusion

Vacuum meters are essential tools for measuring and maintaining vacuum pressure across a variety of applications. By understanding the different types of vacuum meters, their applications, and how to choose the right one, you can ensure that your vacuum systems operate efficiently and effectively. Regular maintenance and calibration are key to preserving the accuracy and reliability of these instruments.

FAQs

What is the difference between a Vacumetros and a pressure gauge?

A vacuum meter measures pressures below atmospheric levels, while a pressure gauge measures pressures above atmospheric levels. Vacuum meters are specifically designed for vacuum systems, whereas pressure gauges are used in standard pressure applications.

How often should a vacuum meter be calibrated?

Vacuum meters should be calibrated regularly based on the manufacturer’s recommendations and the requirements of your application. Frequent use or harsh conditions may necessitate more frequent calibration.

Can a vacuum meter be used in any environment?

Vacuum meters should be used within the environmental limits specified by the manufacturer. Harsh conditions, such as extreme temperatures or corrosive substances, may require specialized meters or protective measures.

What should I do if my vacuum meter is giving inaccurate readings?

If your vacuum meter is providing inaccurate readings, check for common issues such as calibration drift, contamination, or sensor damage. Perform calibration checks and maintenance as needed, and consult the manufacturer for troubleshooting advice.

Are there different vacuum meters for different pressure ranges?

Yes, different types of vacuum meters are designed for various pressure ranges. Choose a meter that matches the pressure range required for your specific application to ensure accurate measurements.